Milling Machine Field Maintenance & Support

Support For Your Milling & Dispersion Equipment

Avoid costly downtime issues and maximize your milling, dispersion, and mixing equipment efficiency with industry-leading support from Hockmeyer! We are dedicated to helping you maximize the potential of your equipment by providing exceptional assistance and support.

FOR WET GRINDING, DISPERSING AND MIXING

-

Milling Technology

Achieve maximum particle size reduction and a tight size distribution with immersion and recirculating mills that achieve outstanding results in a fraction of the time of other milling methods.

View Milling Technology

-

High Viscosity Mixers

Hockmeyer mixers are known to be robust and versatile machines that will continue to generate a strong return on investment year after year.

View High Viscosity Mixers

-

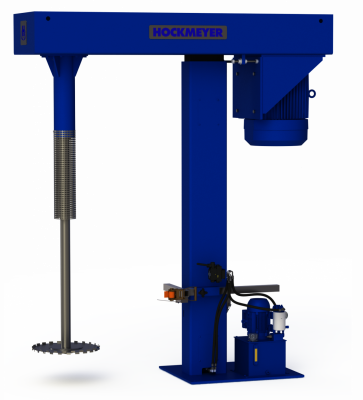

Dispersers and Agitators

Attain a more uniform mix, deagglomerate, disperse, and let-down, while keeping your solutions and slurries homogenized with our line of powerful dispersers and agitators.

View Dispersers and Agitators

-

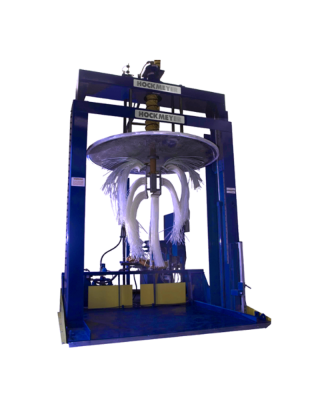

Discharge Presses

Designed for heavy-duty manufacturing applications, our discharge presses are ideal for reducing labor costs while maintaining product quality during product evacuation or transfer. No more scooping or scraping, the press will remove the material from the tank while wiping down the interior walls.

View Discharge Presses

-

Vessel Washer

Effectively and efficiently clean any size tank, tote, or drum in your facility while reducing labor costs and time-to-clean.

View Vessel Washer

-

Accessories

From tanks to blades, we provide a wide range of options designed to expand the abilities of your mixing, milling, and dispersion equipment.

View Accessories

-

Lab Pilot Equipment

Created with flexibility in mind, take your products from benchtop to factory floor without flexible line of lab mills and mixers.

View Lab Pilot Equipment

Test Your Product Free. Schedule a Test Today!

At Hockmeyer, we're committed to making your product the highest quality possible, whether you need milling, mixing, dispersion or agitation. Schedule your product to be tested in one of our demo machines and see the Hockmeyer difference for yourself.

About Hockmeyer

CUSTOMIZED MILLING AND DISPERSION EQUIPMENT. BECAUSE YOUR NEEDS ARE UNIQUE.

Hockmeyer Equipment Corporation has been providing process solutions for over 90 years. A leader in the wet grinding and dispersion industry offering custom-designed equipment of the highest quality available. Our goal is to increase the profitability of our customers through continuous innovations in process technology.

Testing, Parts & Maintenance

Stock Machines & Tanks NEW & USED

Our dedication to customer satisfaction doesn’t stop with the purchase.

Field Training & Support

Hockmeyer is dedicated to providing best-in-class support to maintain the lifespan and efficiency of your Hockmeyer equipment.

Customer Testing-Applications Lab

Don’t trust promises, trust results! Hockmeyer offers it’s Customer Service Laboratory to show you exactly how our equipment will increase your product quality and efficiency!

News & Articles

-

Industry Information

Comparing Basket Mills to Other Milling Technologies: Pros and Cons

-

Dispersers and Immersion Mills

Customizing Mixers, Dispersers, and Basket Mills for Niche Applications

-

Industry Information

The Evolution of Basket Mill Technology: From Traditional Milling to Modern Innovations